SWING-LOCK ADJUSTABLE BULLET RESIZING DIES

NOW AS PROVEN BY HUNDREDS OF SATISFIED CUSTOMERS

PROUDLY MADE IN THE USA

PATENT US 8,459,163 B1

A major step forward for Swing-Lock Muzzleloading has been the development of adjustable bullet resizing dies for sabotless muzzleloader shooting. This development is important because it addresses and simplifies the requirement for bullets which must fit a rifle’s bore with very exact precision.

Because these dies are adjustable, they easily compensate for size variations in bullets from different production lots and small size and structural differences between different brands and types of bullets. Something which is important to understand in sabotless application is that a bullet resizing die will not erase or eliminate those differences. For example, if the shooter has just obtained a new lot of bullets which is slightly larger in diameter than the previous lot, those bullets will come out of the sizing die slightly larger than the previous bullets and may be too tight for proper loading in the rifle. Typical non-adjustable fixed limit dies are unable to compensate for size variations produced by those same variables and it was very common for the need of more than one die to compensate for differences. With the adjustable die, only one die is needed.

Another important consideration which warrants the need for an adjustable die is how a sabotless bullet fits in the barrel’s bore after it has been fouled by shooting. Bullets that have been resized to fit in a clean bore will be a much tighter fit after the barrel has been fouled and may be difficult to load. Whether the rifle shoots best fouled or clean, the adjustable die will provide the compensation needed to produce the correct size bullet.

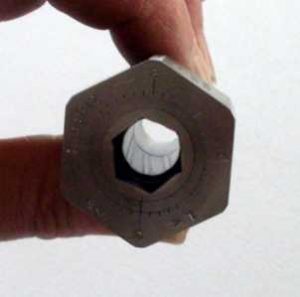

As shown in the pictures below, the new adjustable dies are made to screw into a standard loading press and are easily adjusted through the use of an Allen wrench. The die as sold is provided with an Allen adjustment wrench and a punch that fits into the ram of the press. As of 04 / 2018, there is also a new version die where adjustment is made using a common open end, box, or adjustable wrench. That die does not include an adjustment wrench. The die may also be used with an arbor press if proper support is used and a correct punch is fitted for the press ram.

Regarding the accuracy of adjustment; it is exceedingly easy and precise using the appropriate wrench. The die face as shown below is graduated for reference and the value of each graduation is slightly more than .0001 In. on the diameter. By adjusting between graduations, the shooter can easily adjust the size of bullets by even less than .00005 In. ( 50 millionths ) on the diameter.

Adjustable sizing dies can be made in any caliber and there are two (2) types available. Smooth and Full Form.

The smooth die produces a smooth shanked bullet and corrects for diameter only.

The full form die produces a bullet which is an exact match to a rifled barrels bore geometry. In other words, it produces a bullet that has rifling grooves swaged into its shank. This die functions by utilizing a sizing element that is made from a short piece of the rifle’s barrel and for that same reason it is matched for use with the specific firearm. By external appearance, a full form die looks identical to the smooth die and its functional design is exactly the same.

Some advantages of full-formed bullets are as follows:

- A much better seal is produced because the bullets form fills the rifling grooves.

- The bullets can be sized to load MUCH MORE EASILY while still having a much better seal.

- Because of the superior seal, the reliability of ignition is also better even with easy loading bullets.

- Full-formed bullets typically do not require the use of over powder wads.

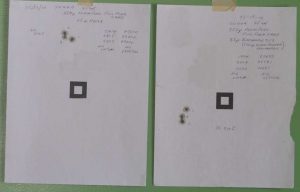

- Because the bullets are automatically engaged to the rifling, high pressure is not required to assure obturation. Low-pressure loads have produced equally good accuracy. See the two targets as shot from a .45 cal. rifle below which illustrate this point.

- Full-formed bullets produce higher velocities with less pressure.

Below are some pictures of the adjustable full form dies and how they function. The smooth die looks and works in exactly the same way. As of 04 / 2018, there is also a new version die that has an external hex adjustment ring which is adjusted using a common open end, box, or adjustable wrench. This die is not shown below but looks very much the same and functions in exactly the same way.

SUMMARY INFO:

Swing-Lock resizing dies are made from tool-grade heat-treated steel for a lifetime of reliable service.

The dies are micrometer graduated and easy to adjust with very high precision.

Dies are available in smooth or full-form versions. An adequate piece of rifle barrel is required for full-form dies.

Dies can be made in any size from .50 caliber and smaller. .45 caliber is standard. .50 caliber and calibers smaller than .45 are special-order.

Dies are threaded 7/8-14 to fit standard reloading presses and include adjustment wrench, punch, and written instructions.

Standard .45 caliber dies are supplied with the new version external hex adjustment ring which does not include an Allen hex key wrench.

COSTS INCLUDING SHIPPING USPS PRIORITY ANYWHERE IN THE USA:

.40, .45, and .50 caliber smooth sizing dies are $160.00

All other caliber smooth sizing dies are $175.00

.458 caliber full-form dies are $180.00

Other caliber full-form dies are $200.00

Costs do not include sales tax

In .45 caliber only, a significant price discount is allowed if 10 or more dies are purchased. For info, call, text, or send e-mail to:

SWING-LOCK CUSTOM MUZZLELOADING, INC.

Phone: (814) 440-7292

E-mail: thomas@swinglock.net

TO ORDER:

Send check or money order to:

Swing-Lock Custom Muzzleloading, Inc.

255 Taylor Ln

Julian, PA 16844

If you have any questions regarding adjustable bullet sizing dies or would like to place an order, please call or text (814) 440-7292 or send an e-mail to swinglock@velocity.net or thomas@swinglock.net and I will be happy to help you.

Thanks,

Thomas Post

President

Swing-Lock Custom Muzzleloading, Inc.